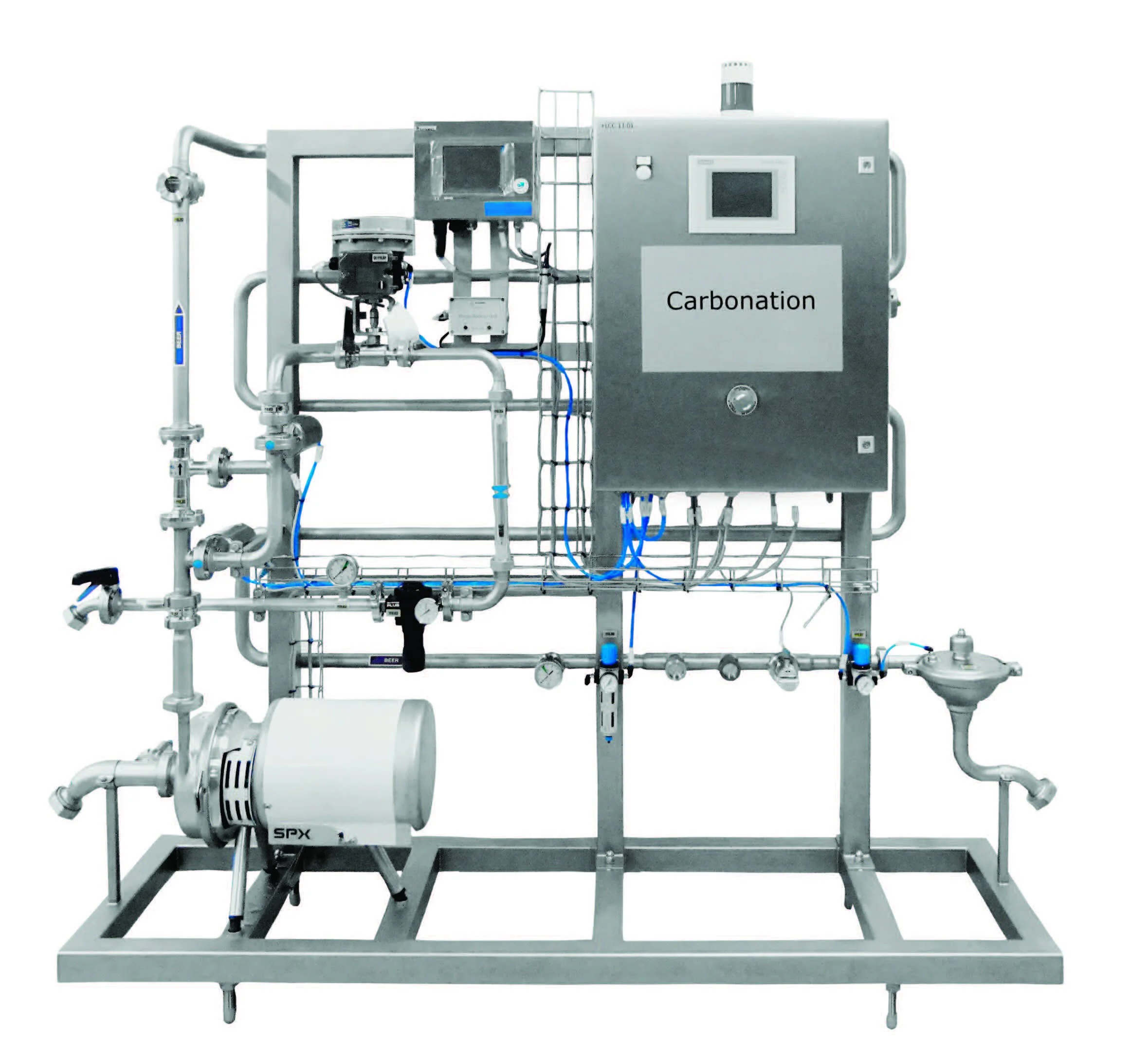

PROCESS UNITS

Inline

Carbonation

Automatic Unit

For instant beverage carbonation

Micro bubble size

Instant saturation

Precise CO2 injection

CO2 analyser controlled

-

CO2 is an essential ingredient of carbonated beverages. It enhances flavour and body of the product and the effect of effervescence characterises the refreshing taste of the beverage.

The CO2 content also influences beer foam structure and its stability. Therefore, consistent and accurate CO2 is one of the main quality factors in the production of beer and soft drinks.

Designed for fast and accurate injection and dissolution of CO2, this unit provides a fully automated solution for continuous carbonation.

-

CO2 is injected into the beverage, which splits the gas into micro bubbles. Most efficient and instant dissolution of CO2 is achieved with only a minimal pressure drop, no gas loss and a fully hygienic design. No static mixer, sinter candles or recirculation tanks are needed.

The system is PLC controlled and has automatic modes for continuous carbonation and CIP. The selective inline CO2 analyzer continuously monitors the CO2 concentration. The output signal is processed by the PLC to control the CO2 dosing. A high precision control valve accurately adjusts the CO2 injection, avoiding any over or under carbonation.

The back pressure valve maintains constant pressure in the system despite any changes in flow. Constant system pressure ensures fast and accurate control of CO2 dosing.